Over the years, the shift from manual to software-based processes has been a game-changer for productivity across various industries. In the realm of Governance, Risk, and Compliance (GRC), where accuracy and timeliness is essential, the contrast between manual and software-based systems stands out and we have real-world examples to demonstrate it.

Many organisations, however, still manage their compliance through manual processes or semi-manually using multiple software tools. These approaches lead to reduced effectiveness as manual compliance processes are prone to human error (that take time to identify and resolve) and information-flow delays (that can affect decisions and corrective actions).

Integrated software-based processes, and GRC software specifically, substantially reduce error rates and correction time. But by how much exactly?

Keep reading to discover how manual and software-based compliance systems compare in terms of error fix time by industry.

In health services, the Royal Australian College of General Practitioners (RACGP) found that administration consumes up to 20% of total time (Cit. RACGP study)

Other studies suggest that manual data entry leads to error rates between 10% and 20%, whereas electronic systems reduce these errors to approximately 1%–3% . Also the time required to identify and correct errors using manual systems can consume 20%–50% of administrative time, while software-based solutions can reduce this to 5%–10% . (Cit. BMJ & JMIR).

Manual tracking in supply chain and logistics operations can result in errors in 3%–5% of transactions, requiring 25%-35% of administrative time for corrections.

Software based systems, and automated tracking technologies, have been shown to reduce error rates to less than 1%, cutting correction time to 5%-10% . (Cit. Rookconnect).

The warehousing and distribution industries were one of the early adopters of data entry and reading automation given the enormous volumes of items they process.

Using a barcode scanner to record (scan out) or identify (scan in) numbers—such as part numbers, manifest numbers, or SKUs—has an error rate of roughly 1 in 3 million scans. In contrast, manual recording and verification typically result in error rates between 1% and 4%.

Integrating barcode scanning into compliance controls—such as product quality controls, service delivery inspections, audits, or equipment maintenance—eliminates the need for manual data entry and reduces information field errors to near zero.

Manual tracking in supply chain and logistics operations can result in errors in 3%–5% of transactions, requiring 25%-35% of administrative time for corrections.

In manufacturing, errors not only affect product quality but also increase rework and scrap rates leading to higher operational costs.

Information-related sources of errors can be:

For manual compliance controls, even though error rates may only be between 1% and 4% of data entry fields, it’s the flow-on effect of un-corrected errors that compounds the scale of the problem in the manufacturing process.

In addition to data automation and validation, manufacturers can look at:

In the services sector, invoicing to clients and payment of service providers is typically highly variable. Managing WHS risk is also variable depending on the work environment of the day.

Given a manual data entry error rate of 1% to 4% per data entry field, and the typically large amount of information that needs to be gathered to create a traceable record of the service delivered, errors can compound rapidly and can also become systematic if undiscovered or unmanaged for too long.

Research studies by EY Sweeney and L.E.K reveal that in trades such as electrical and plumbing, administration can take up to 14hrs/week or 35% of the available time (Cit. Tradie Economy)

These tasks can, in many cases, be automated and those components that cannot be automated, i.e. those that rely on know-how and collating information from other sources, can be streamlined through appropriate software systems.

All organisations have finance and accounting departments that deal with the beginning of the business’ value chain (accounts payable) or the end (accounts receivable).

Quality compliance errors will eventually manifest themselves in billing or payment errors or credits.

In organisations where operational compliance controls are wholly manual these errors can consume 30%–40% of administrative time to detect and correct. Automating and validating data entry, reducing manual errors and stopping erroneous information from proceeding down the value chain has shown that financial errors in invoicing and payments can be reduced by up to 40% (Cit. ERP statistics)

Conversely, electronic systems that have robust automation and information validation features reduce the associated correction time to less than 5% of total administrative time. (Cit. Integrationmadeasy).

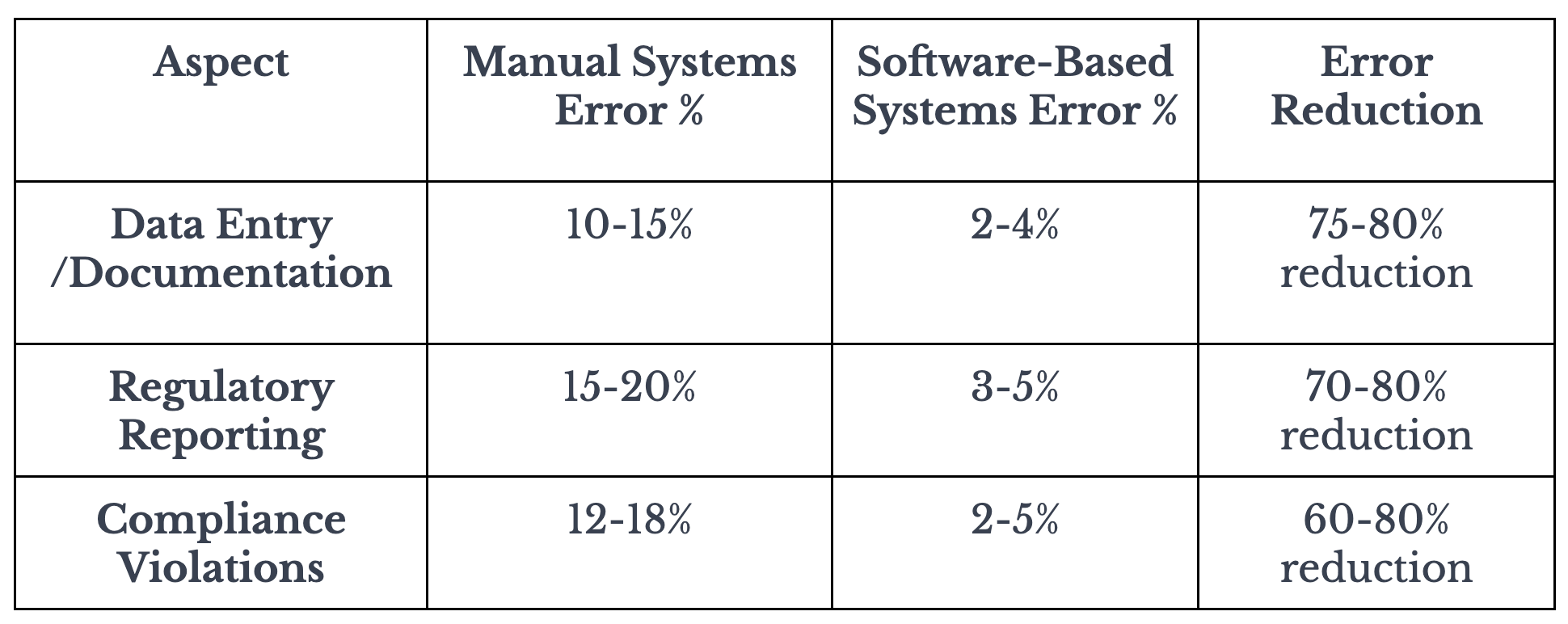

Deloitte’s 2021 Compliance Survey, shows that manual compliance processes suffer from error rates ranging from 10-15% in data entry and contributed to 12-18% of compliance violations. These errors range from scattered or lost files to human oversight leading to missed deadlines and audit failures.

Conversely, software-based compliance systems have error rates of 2-5% with studies like Forrester’s 2024 analysis, showing a 75% reduction in documentation errors.

The White & Case 2023 Compliance Risk Survey further confirms a 60% error reduction in compliance management through automated workflows and centralised storage.

The table below summarises these findings, highlighting the stark contrast in error rates and the time-saving of software based compliance solutions vs. manual.

Businesses in Australia are looking everywhere for productivity growth. The decline of Total Factor Productivity in Australia has many causes.

By implementing Governance, Risk & Compliance software and integrating all operational compliance controls from quality, WHS and environmental in one holistic package, businesses can obtain many benefits.

Tools like ISOPro offer customisable modules that adapt to your business needs, reduce error rates and the time to fix them when they happen, irrespective of whether you operate in manufacturing, healthcare, logistics or trades/skilled services.

Our platform provides a flexible GRC solution designed for collaborating teams, ongoing compliance evolution and the need to “be sure”, especially in highly regulated industries.

With rules-based automation guiding your work and information flows, your team can reduce administrative effort and errors thereby increasing efficiency, effectiveness, productivity and capacity.

The platform offers organisation-wide visibility, on-demand reporting, and seamless integration across all compliance areas.

User support by a dedicated team ensures compliance changes are deployed quickly and with minimal, or no, disruption to the business.

Let’s discuss how ISOPro can automate your compliance administration. Get in touch today!

Co-Founder / CEO